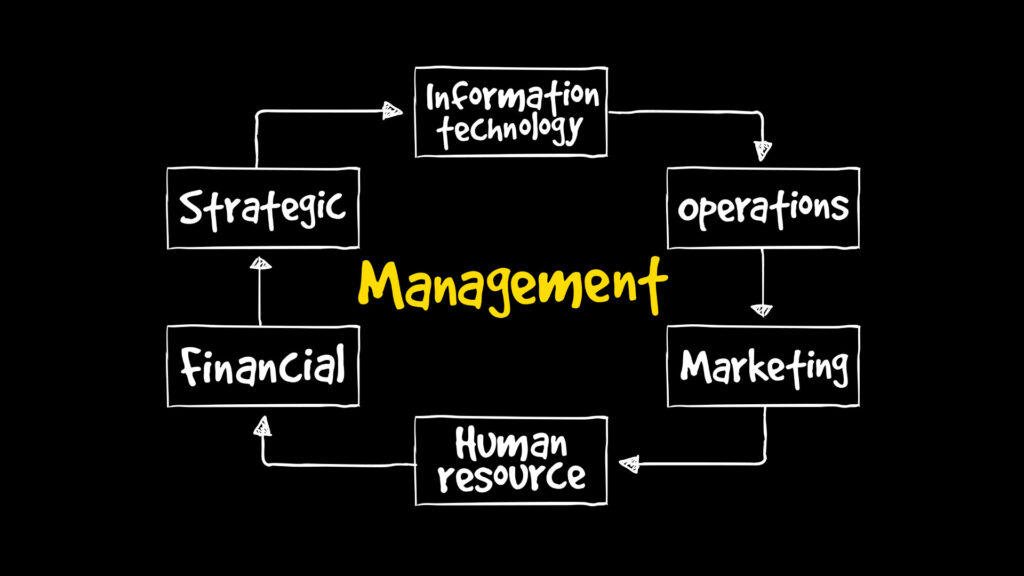

MedTech innovation, previously identified by the isolated advancements in surgical methods and medical devices, has evolved into a vast ecosystem of interprofessional collaboration. Demands for clinical services and global scrutiny of regulatory requirements and the pressure to speed up time-to-market have led to a complex set of requirements across quality assurance, engineering, regulatory affairs, quality assurance, as well as supply chain processes. Each of these areas typically is a digital entity with its tools, workflows, as well as knowledge bases, resulting in disconnects which can hinder progress rather than speed it up.

The problem that many medical device companies face present day is a dispersed digital infrastructure that prevents integrated control. From initial ideation to the delivery of products to market the digital process is usually a maze of silos – Product Lifecycle Management (PLM) systems which do not communicate to Manufacturing Execution Systems (MES) and Quality Management Systems (QMS) which are far from ERP platforms that interface with suppliers. These gaps create inefficiencies, duplicated efforts, and result in costly compliance issues, especially when devices become more complex and the regulatory burden increases.

Although some companies try to build an amalgamation of their digital tools using middleware or APIs and middleware, it often results in unstable systems, which can be hard to manage and scale. Fragmentation isn’t just an inconvenience for technical reasons; it’s a risk to strategic stability. In high-risk, highly controlled areas such as MedTech and healthcare, the absence a connected digital backbone can pose a danger not only to the timelines for products, but also to the patient’s outcomes as well as corporate reputation.

A Unified Platform for Traceability and Compliance

The key to resolving this issue is the creation of an unifying source of truth throughout the entire product development lifecycle. This method ensures that traceability will no longer be a retrospective task that’s left to the documentation team, but an integral part of every process and design decision. With the regulatory requirements becoming more complex across international markets, this type of oversight is no longer only beneficial but vital.

A few companies are working on platforms to meet this demand. For instance, solutions provided by companies such as Enlil, Inc. intend to offer a cloud-based development traceability platform that is specifically tailored to the MedTech sector. In contrast to traditional tools that focus on specific areas such as ERP or QMS, these platforms aim to combine PLM, MES, ERP, and QMS functions in a single, integrated ecosystem. The integrated nature of these platforms allows OEMs as well as contractual manufacturers, consultants for regulatory compliance, as well as design and development partners, to join forces in a unified and compliant data environment.

In ensuring that all stakeholders, whether in clinical affairs, engineering, or supplier management, can access the exact data that they need, these platforms eliminate problems with versioning, remove duplicate approvals, and improve the speed of decision-making in real-time. This transparency improves the compliance outcome while also supporting more rapid innovation and iteration. In the end, integrated traceability is the driving force behind operational efficiency as well as the security of success in regulatory compliance.

The Risk of Disconnected Systems in Regulatory Landscapes

In a sector where oversight is rigorous and the price of non-compliance is substantial, dispersed systems can be risky. Regulators around the world, such as FDA, EMA and increasingly the FDA, EMA, and increasingly APAC agencies, require detailed documents and evidence of the rigors of the process throughout the development cycle. But the absence of systems makes it difficult to create thorough, audit-ready records without significant manual effort and retroactive verification.

The challenges are especially acute in products that use AI-enabled diagnostics, software components, or treatment tools that are customized. In these instances, documentation should reflect iterative development of risk assessments and post-market surveillance strategies in a manner that is identifiable and connected. Traditional systems usually require teams to collect data across multiple databases, enter the data by hand, or use outdated templates that don’t conform to current regulations. Human errors, data loss, and misalignment are more likely in these situations.

Additionally, when businesses work with suppliers and contract manufacturers across different countries, ensuring compliance can be a challenge. Without a central backbone, companies could encounter duplicate validation procedures or struggle to make sure partners are in line with most recent modifications or changes to the design. A fully integrated digital infrastructure assures continuity, facilitates global collaboration, and shields firms from the financial and reputational damage that comes from late submissions or audits that fail.

Facilitating Cross-Functional Collaboration since Day One

Effective product development for successful product development in MedTech requires input synchronized from a variety of stakeholders. Human factors experts, clinical experts, engineering consultants for regulatory manufacturers, and software development teams all require access to similar data. In many companies these teams operate in functional silos and communicate through spreadsheets and email chains, rather than via open platforms that foster the transparency of information and speeds.

Digital backbones that are integrated change this concept by providing an integrated platform that allows for modifications, requirements, and other decisions to be readily available to all users who are authorized. This allows teams to accelerate their development without losing sight of any regulatory ramifications or quality benchmarks. Instead of focusing on compliance as an independent process, it is now an integral part of the development and design culture. Risk assessments are conducted collaboratively, and change requests are immediately accessible across departments, and test results can be linked to designs in real-time.

This alignment is particularly crucial in the process of design transfer and the beginning of manufacturing. Uncertainty during these stages could cause tooling mistakes as well as batch failures and interruptions in the supply chain. A system that is integrated ensures that the original design is kept when the product is moved from CAD drawings to use in clinical settings. Teams can be confident in their work and be assured that the product produced is a reflection of what was approved, tested, and verified.

From Operational Efficiency to Strategic Agility

Efficiency is not a luxury anymore in MedTech and is now vital to survive. The speed of change, especially in diagnostics and connected health, is a call for companies to reduce their time-to-market without compromising quality. Digital backbones integrated with digital technology help through automation of repetitive work, streamlining the documentation, and enabling workflows that adjust to changes instead of resisting them.

The ability to think strategically is equally important. Businesses must be able to change their strategies in response to changing rules, market feedback, or disruptions to the supply chain. If the systems are siloed, these shifts can be difficult and risky. Platforms that are integrated, however they allow rapid process reconfiguration and reprioritization. Any design changes triggered by post-market feedback is identified, implemented, and then validated without having to start from the beginning. Product roadmaps evolve into live documents that are based on real-time information instead of static forecasts.

Additionally, integrated systems offer better allocation of resources. Leaders are able to see what projects are struggling and which suppliers are not performing, and what gaps in documentation are present. This data aids in planning, budgeting, managing risk, and planning for go-to-market. In a business which margins are extremely tight and the need for constant monitoring of operational excellence can translate directly into competitiveness in strategic terms.

Empowering the Extended Ecosystem: Beyond OEM Walls

Modern MedTech development does not occur in isolation. Original Equipment Manufacturers (OEMs) frequently rely on contract design companies, as well as software developers, clinical trial partners, as well as suppliers from around the world to bring products to the market. Each of these players plays an important role, but conventional systems view them as outsiders and often restrict access or demand duplicate data entry.

An integrated digital backbone is a new way to define the notion of collaboration by expanding its capabilities beyond the walls of companies. It gives security-grade access to role-based users, which ensures that partners from outside can take part effectively in the process of development without compromising the integrity of data as well as intellectual property. Contract manufacturers receive current specifications, and regulatory consultants are able to review documents in context, and design consultants can make sure that their work is in line with current risks and requirements.

In bringing together all development organizations in one place, businesses can eliminate obstacles and promote a sense of sharing accountability. Transparency results in more effective communication, fewer delays, and better alignment with strategic goals. This improves efficiency, but also creates trust between partners over the long term, which is essential in a field that is defined by the complexity of its operations and rapid advancement.

Looking Ahead: The Future of MedTech is Seamless, Intelligent, and Connected

What’s to come from MedTech is not shaped exclusively by technological advances or changes in regulation, and the capability of businesses to use data as an asset for strategic planning. Integrated digital backbones provide the necessary infrastructure for this change to be realized. They act as the connecting tissue between delivery and design, and between compliance and innovatio,n as well as between data and decisions.

The future of artificial intelligence, predictive analytics, and well as machine-learning will in the future depend upon the high-quality and comprehensiveness of the information gathered during the lifecycle of development. Systems that are dispersed cannot be able to support this new revolution in intelligence. But, platforms designed for traceability, cross-functionality, and scalability are the best foundation for MedTech companies to shift from compliance that is reactive towards proactive and innovative.

A complete digital infrastructure is much more than just a productivity tool. It is a strategic differentiation. In an industry where stakes are high and the margins of errors are extremely small, businesses that invest in a solid technological backbone won’t just satisfy the needs of today but also be able to be the leaders of the future. The integration of systems will differentiate those who are leading from those who follow and will transform the ways MedTech provides healthcare to all of the world.